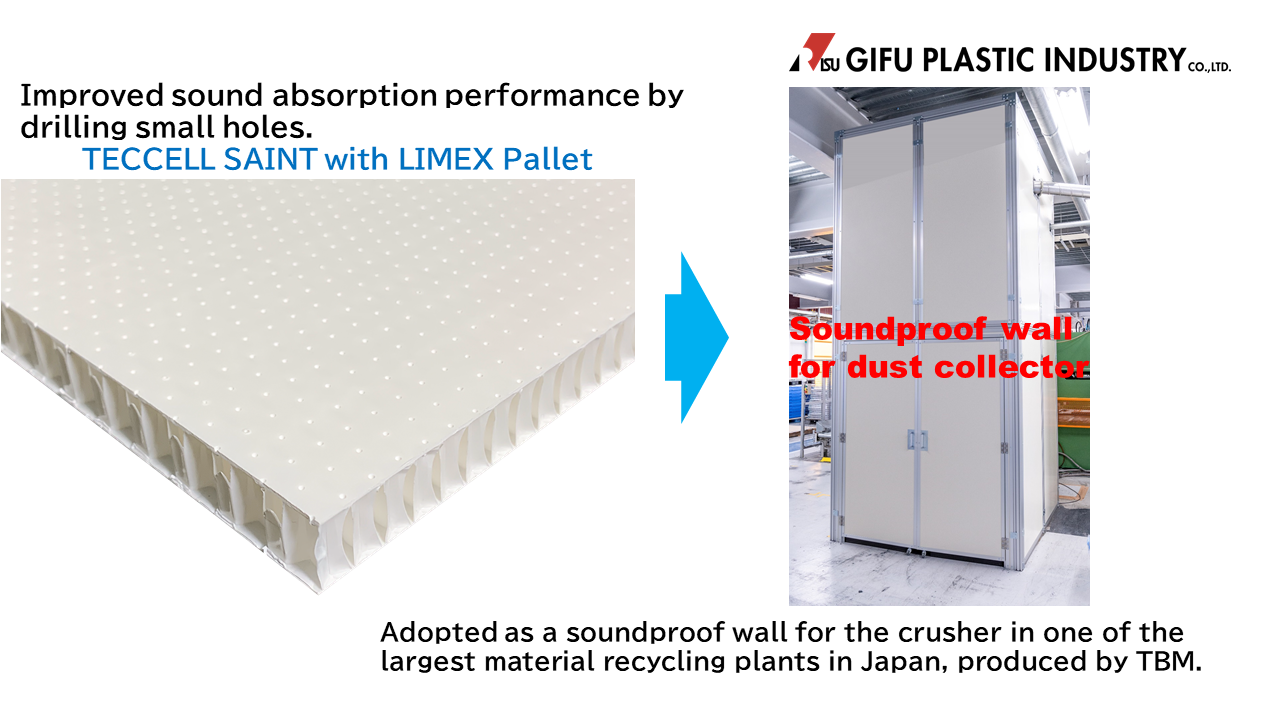

RISU Group's Initiative for the Environment

Efforts to Reduce Usage

From the design and conceptualization phase, we are actively engaged in the development, dissemination, and promotion of environmentally conscious products through the principles of Eco-conception (environmentally conscious design).

Reduce : Tray Stacking Optimization

Optimizing tray stacking by lowering the profile of trays enables the reduction of weight and space during transportation, contributing to CO2 emissions reduction.

Renewable : Lightweighting of Pallets

By integrating reinforcing materials through a single-forming process, we achieve enhanced structural integrity in pallets. This approach not only leads to lightweighting but also results in a reduction in material usage, contributing to sustainability.

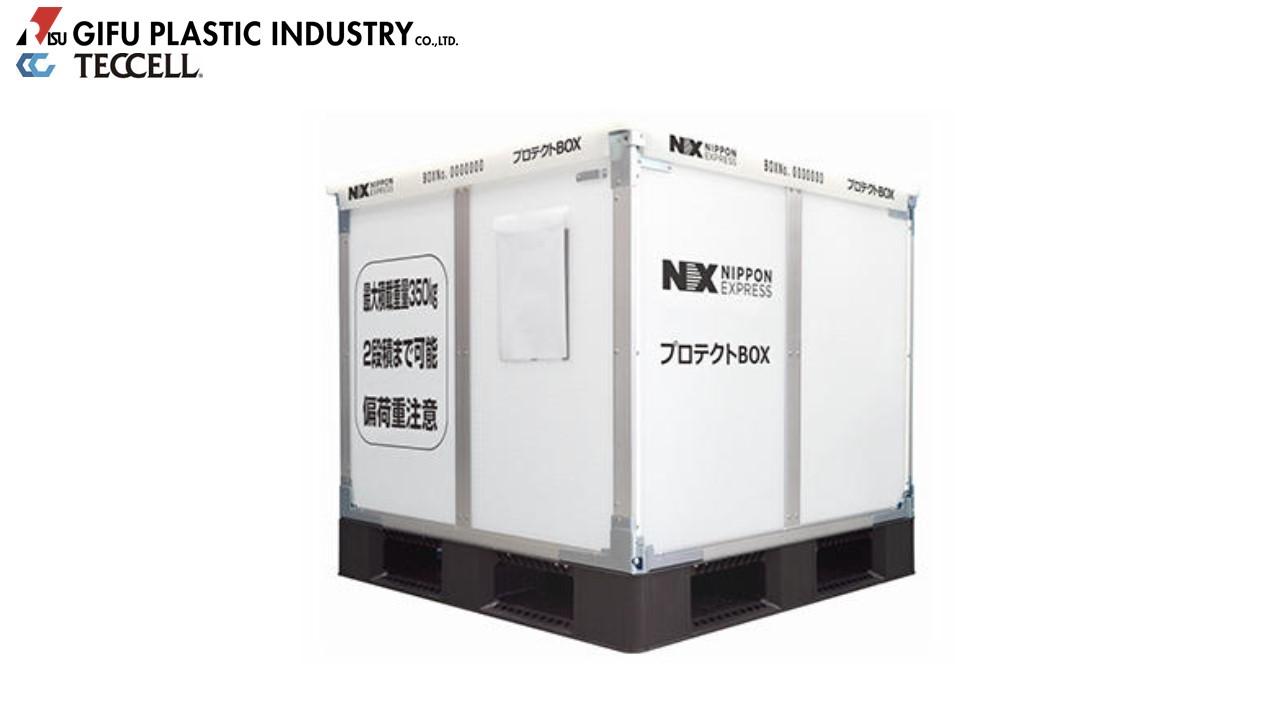

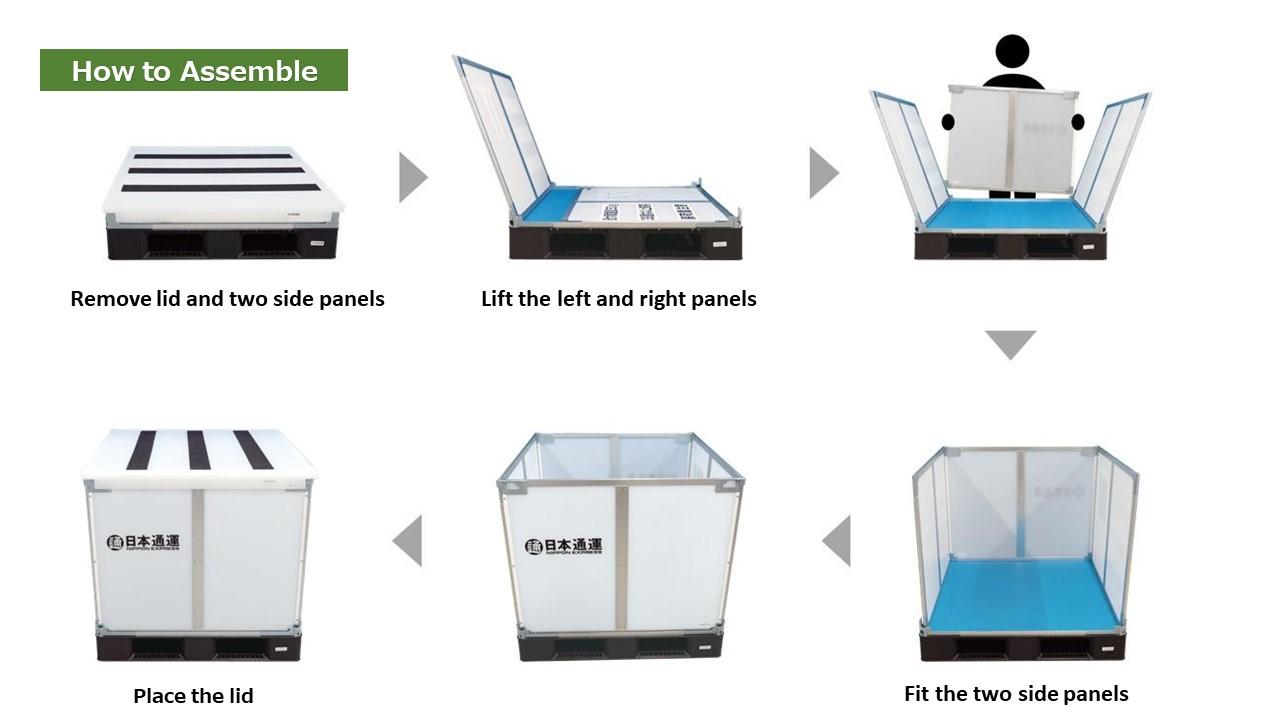

Reduce : Easy Assembly and Foldability

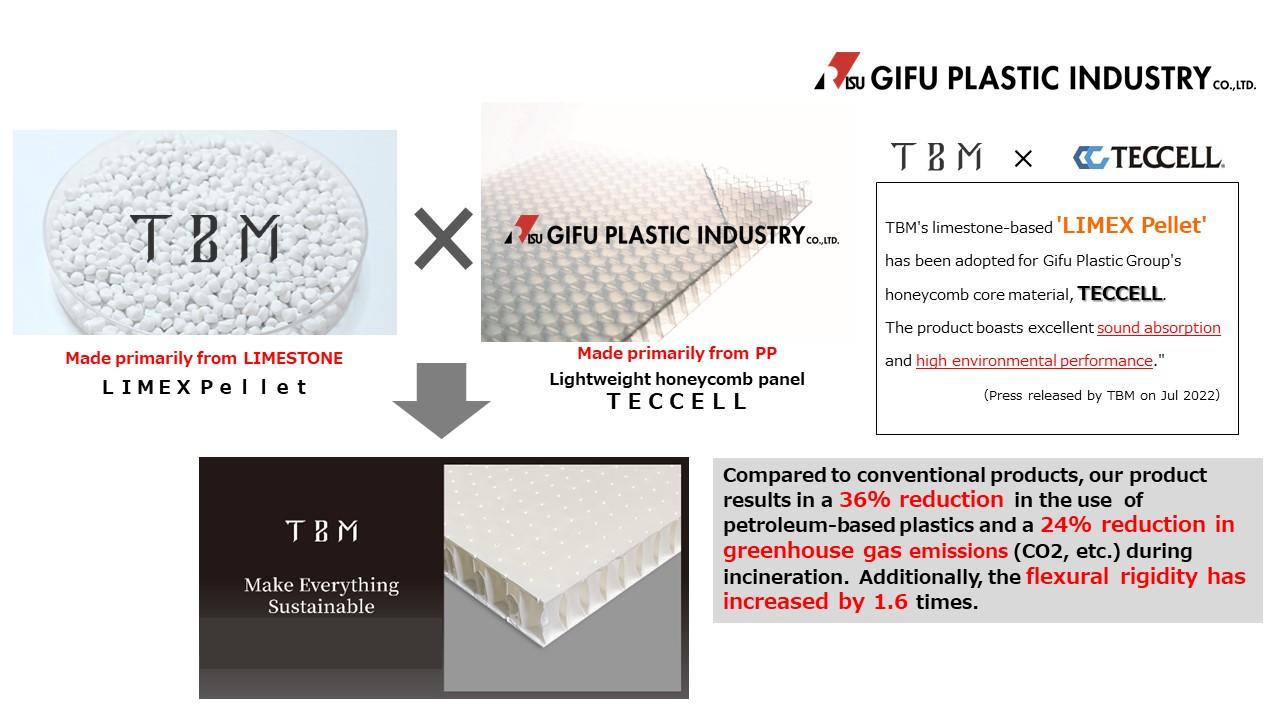

The jointly developed "Protect Box," in collaboration with Nippon Express, enhances customer transportation efficiency, transport quality, cost reduction, and environmental contributions. Utilizing lightweight and robust honeycomb core material, known as "TECCELL," the product ensures secure protection of goods.

The ease of both assembly and folding, coupled with the use of "TECCELL," eliminates the need for excessive packaging materials and cushioning, resulting in a reduction in waste generation. This eco-concept logistics material is designed to minimize environmental impact.

<How to Assemble>

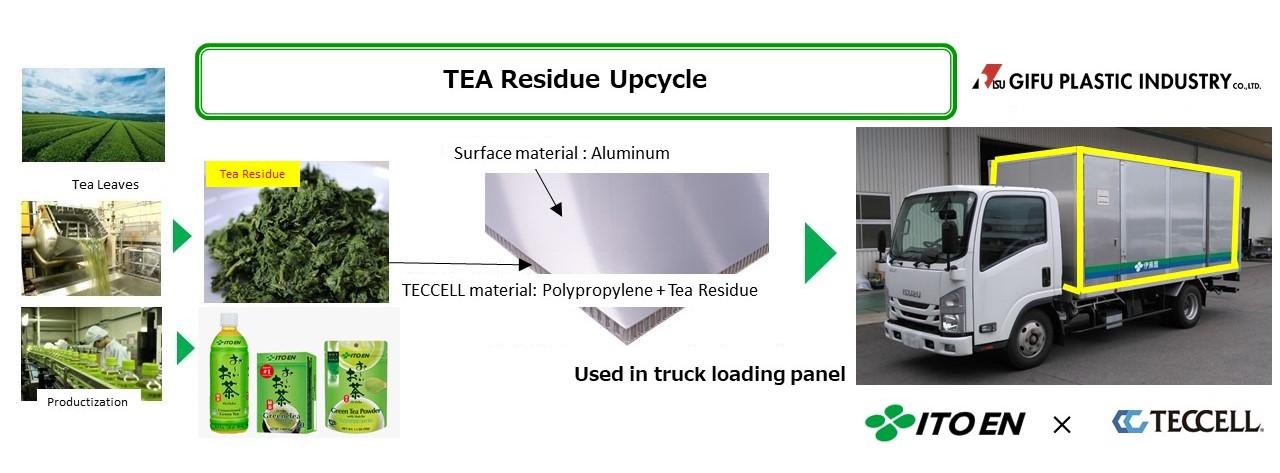

Reduce : Lightweight Panel with Tea Residue Blend - Joint Development with ITO EN

Contributing to the reduction of petroleum resources and the mitigation of carbon dioxide emissions, TECCELL honeycomb panel is characterized by its lightweight and high rigidity. Leveraging ITO EN's "Tea Residue Recycling System," we have developed the "Tea Residue Blend Lightweight Panel." This panel incorporates a thin aluminum layer on the surface and has been utilized in the framework of ITO EN's delivery vehicles.

- By adoping this panel as a substitute material for non-ferrous metals in the framework components of delivery vehicles (such as slide doors, rear doors, and flooring), we have achieved a maximum weight reduction of up to 110 kg when compared to conventional vehicles.

- The door opening and closing require approximately one-third less force compared to conventional slide doors and rear doors.

- If implemented across ITO EN's entire fleet of delivery vehicles, it is estimated that a reduction of approximately 750 KL of petroleum resources (by volume) and a consequent reduction in carbon dioxide emissions of approximately 1,930 tons can be achieved.

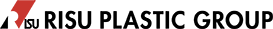

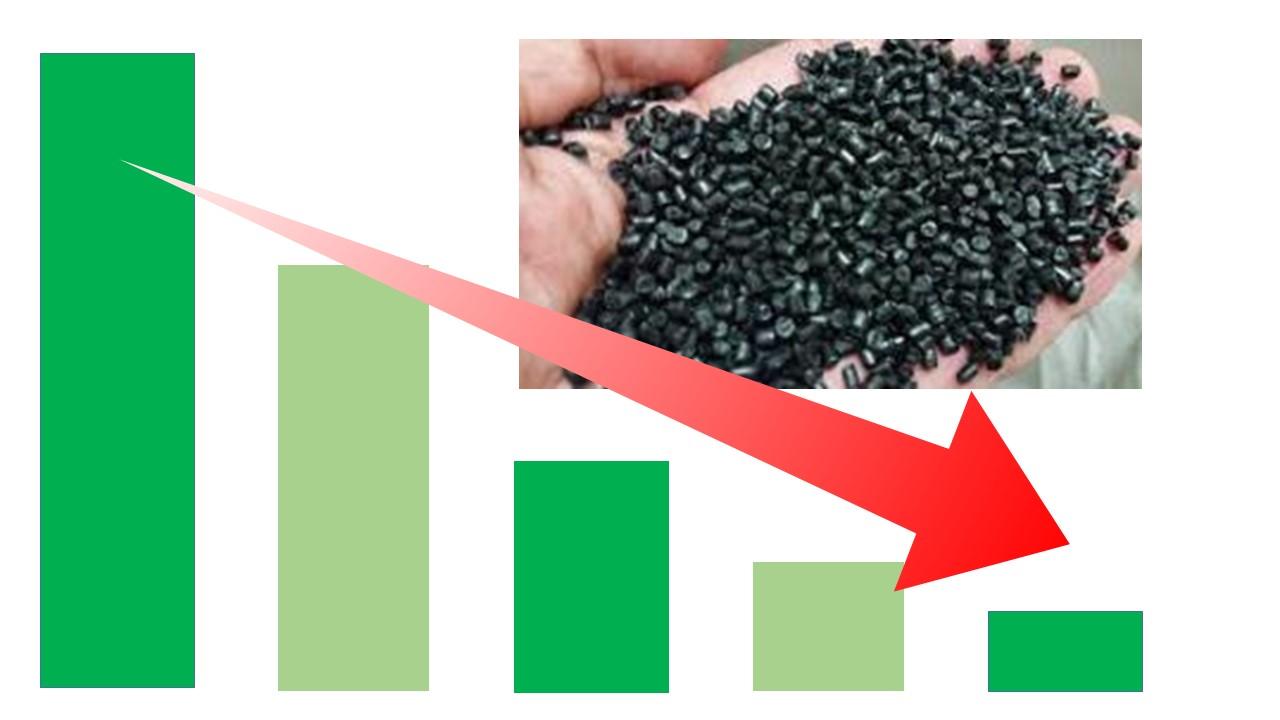

Reduce <LIMEX+TECCELL>

We have augmented our product range by incorporating TBM Co., Ltd.'s "LIMEX Pellet," which is primarily derived from limestone, into the "TECCELL" (Honeycomb Panel), primarily composed of polypropylene (PP). "TECCELL" is known for its polypropylene base, while TBM's "LIMEX" contains more than 50% inorganic materials, including calcium carbonate. This integration results in LIMEX-manufactured TECCELL, which offers superior environmental performance and improved strength characteristics.

LIMEX : A Definition and Its Environmental Attributes

LIMEX is an inorganic filler-dispersed composite material that comprises over 50% inorganic components, including calcium carbonate. With limestone as its primary ingredient, it is possible to contribute to the preservation of high-risk, depleting resources like petroleum, water, and forest resources when manufacturing alternative products to plastics and paper. Its environmental performance is assessed through the scientific methodology of Life Cycle Assessment (LCA), which analyzes the environmental impact throughout the product's lifecycle, from raw material procurement to production, distribution, usage, and disposal.

LIMEX has gained wide adoption, with over 8,000 companies, municipalities, and more worldwide. It holds patents in over 40 countries and has been showcased at international conferences such as COP and G20. Recognized as a prime example of Japanese technology, it is registered on UNIDO's Sustainable Technology Promotion Platform (STePP).

*UNIDO : United Nations Industrial Development Organization

It is officially defined as "Inorganic-Organic Composite Material with Inorganic Components as the Primary Constituent (JSA-S1008)" by the Japanese Standards Association (JSA).