RISU Group's Technology Information

RISU Plastic Group boasts a wide array of molding technologies and facilities, meticulously aligned to accomodate the diverse requirements of our clientele. Our production processes are executed within an environment that not only emphasizes stringent quality control but also upholds rigorous hygiene management, ensuring the highest standards in product manufacturing.

Technology List

Injection Molding

Injection molding is a forming technique suited to large-scale production of products with complex shapes. We use injection molding mainly for things like logistics industry materials, industrial components, medical related products, household products, commercial-use goods, and construction and engineering materials.

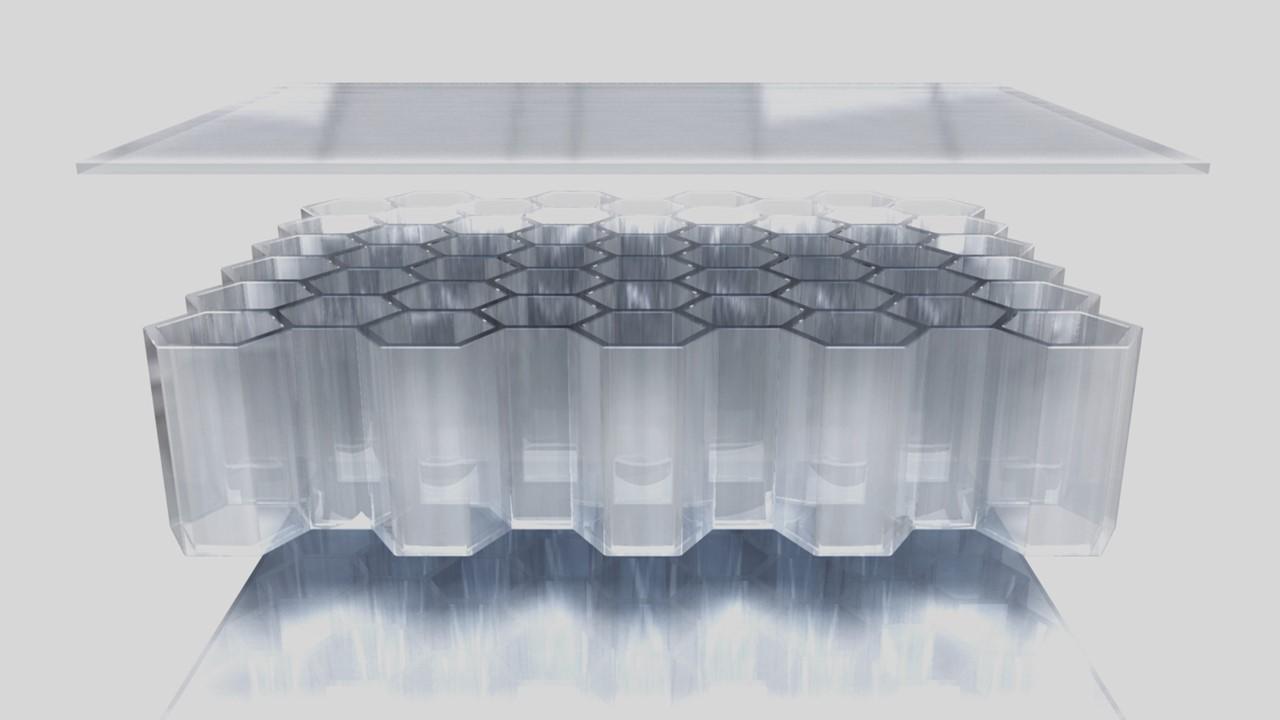

Production System for Food Packaging Containers

Considering food packaging containers as an integral part of the food itself, we maintain exceptional product quality throughout the entire production process, from sheet material to finished products. Our integrated system ensures a consistent focus on hygiene, quality, delivery schedules, and cost-efficiency, aligning with our commitment to stable supply, and peace of mind.