RISU Group's Initiative for the Environment

Reuse : Initiatives in Sustainable Design

We actively engage in the development, promotion, and propagation of environmentally conscious products, incorporating the principles of Eco-conception (environmentally conscious design) from the early stages of the design process. This proactive approach aligns with our commitment to sustainable practices and the circular economy, emphasizing the reuse of materials and resources to reduce waste and minimize environmental impact.

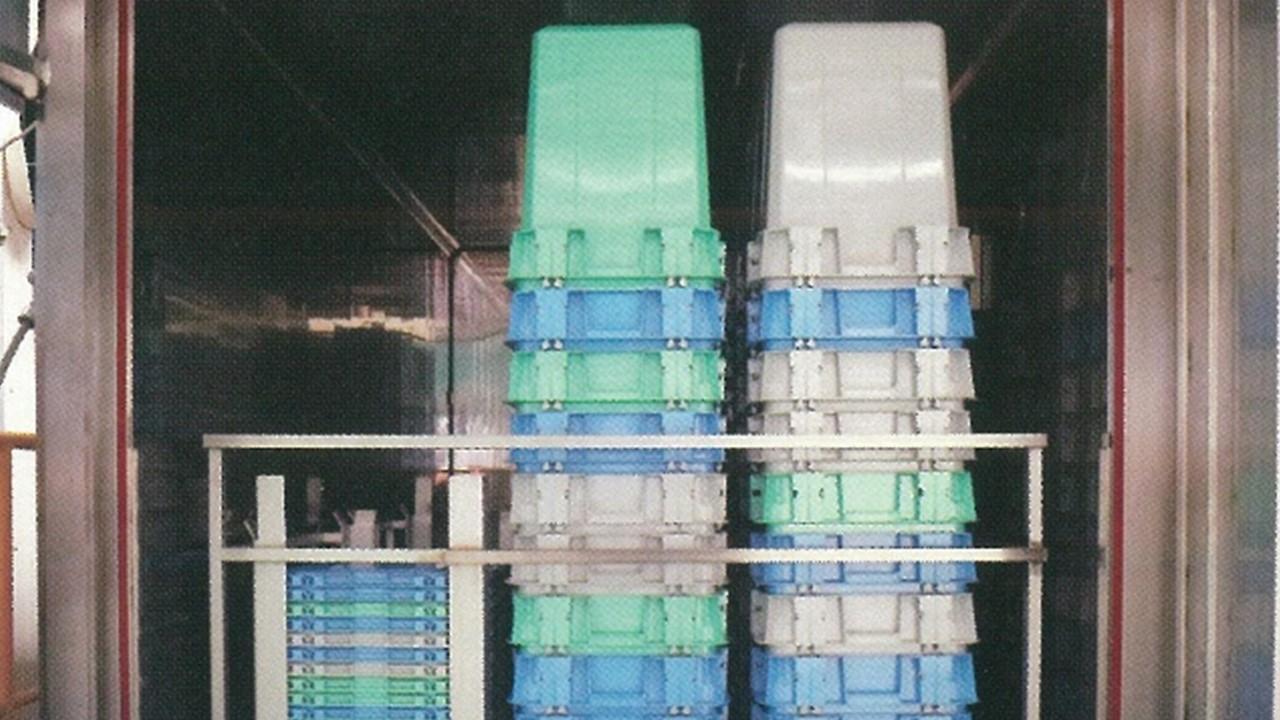

Medical Waste Containers - Cycle Pail

Development of Medical Waste Containers - CyclePail

- ① Infectious medical waste generated in healthcare facilities is typically collected using polypropylene (PP) resin containers and disposed of through incineration or melting. However, from an environmental sustainability perspective, there was a demand for reusable storage containers that could be heat-sterilized, reducing the environmental footprint.

- ②Nevertheless, traditional PP resin containers suffered from low heat resistance, making them prone to deformation at high temperatures and unsuitable for sterilization processes. Additionally, low-strength containers posed safety concerns, as sharp objects such as needles could penetrate them.

- ③ In response to these challenges, containers made from a compound resin of polycarbonate (PC) and PP resins were jointly developed with Japan Shooter Co., Ltd. and TEIJIN LIMITED. These containers can withstand high-temperature sterilization processes and offer high strength. They have contributed to the realization of Japan Shooter's "CyclePail System," a container recycling system for the management of infectious medical waste.

Waste Reduction and Cost Savings

We achieve waste reduction in the disposal of infectious medical waste by discarding only the contents. Additionally, the reuse of containers leads to cost savings.

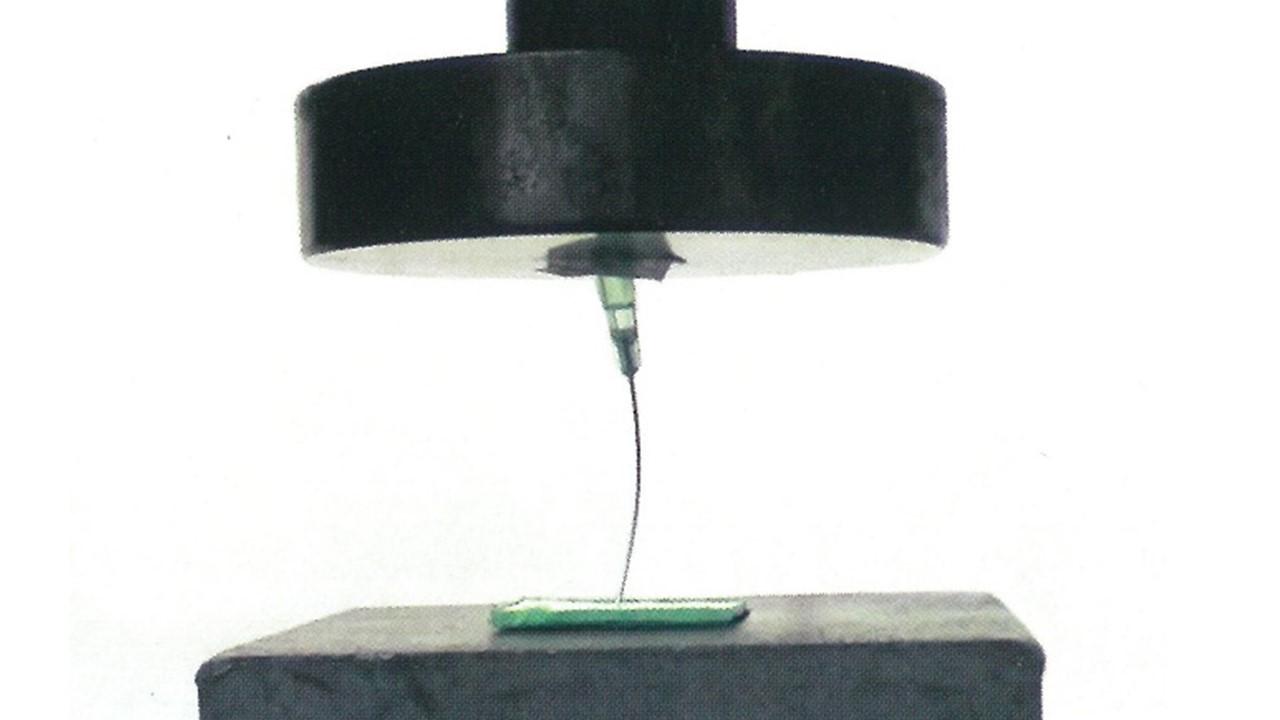

Needle Penetration Strength Doubled

The needle penetration strength is now twice as strong as conventional containers. Utilizing a PP/PC alloy, ensuring the safer disposal of sharp objects.

30% Increased Heat Resistance

Utilizing a PP/PC alloy, the containers can withstand high-pressure steam sterilization at 121°C, improving their heat resistance by 30%.

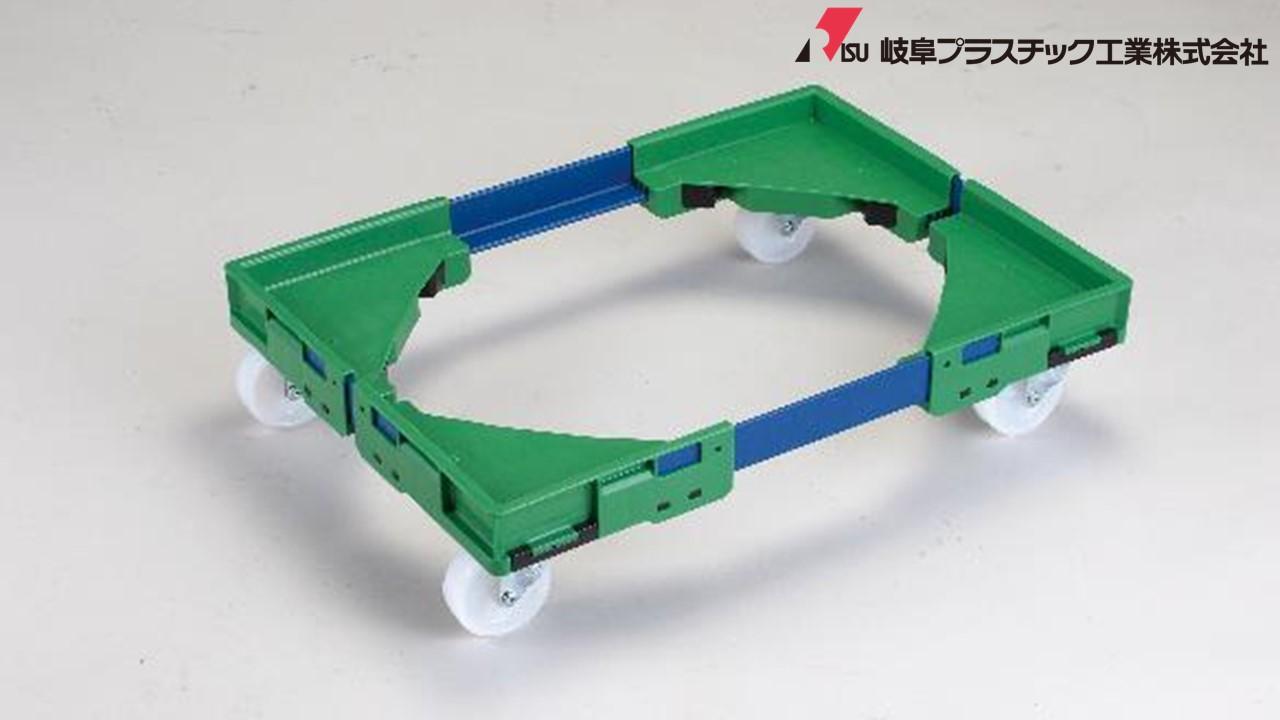

Boltless Carrier

The Boltless Carrier is an eco-concept product designed for easy sorting and disassembly, facilitating recycling. This product enables straightforward assembly and disassembly of the frame, corner parts, and casters.

Being boltless, it simplifies the repair or replacement of casters even in case of damage or rust, and it allows for easy material separation during disposal. This environmentally-friendly product promotes ease of recycling.