Technical Infomation

Advanced facilities and high technical expertise in plastics

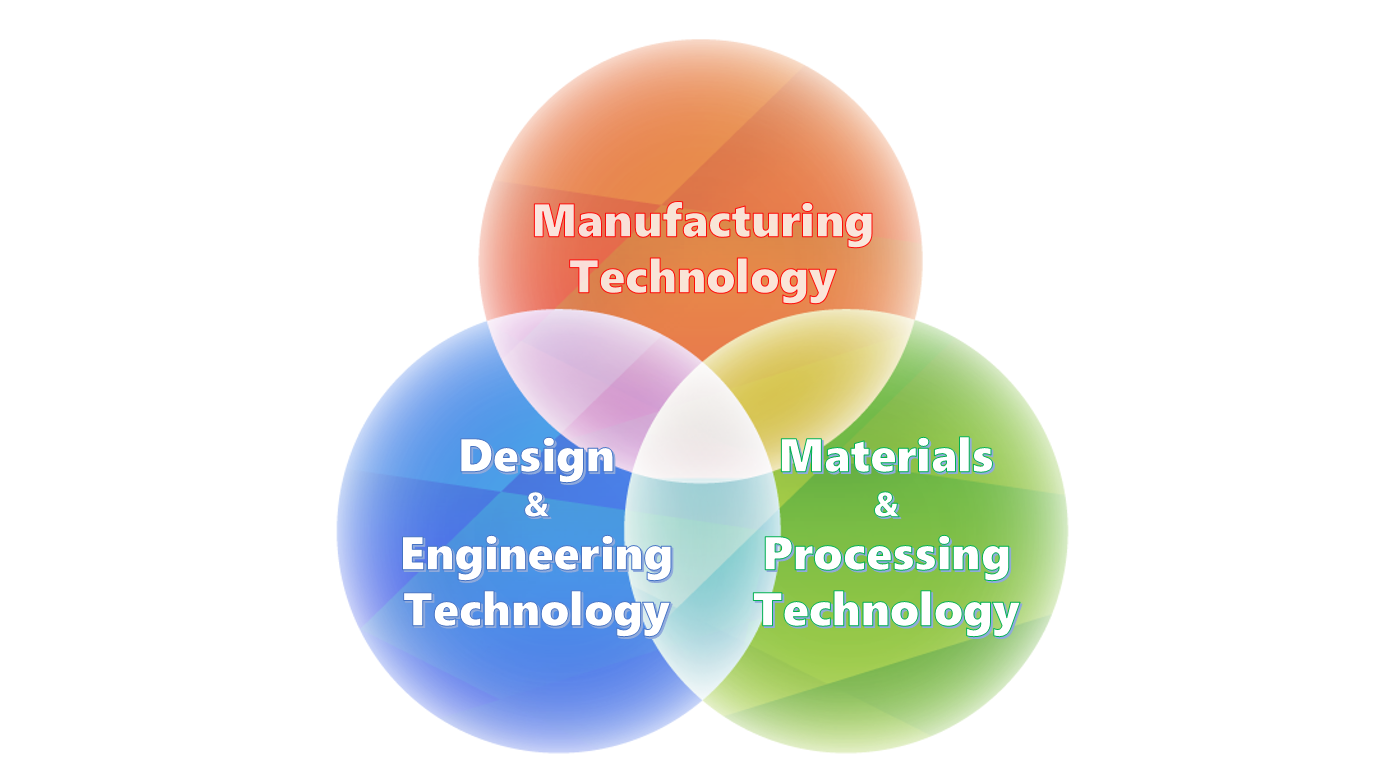

Technologies Cultivated as a Technology-Driven Company

At the RISU Plastic Group, we have embraced the challenges of the early days of plastics and recognized its limitless potential as a technology-driven company.

Through unwavering dedication to our customers' needs, we have cultivated expertise that cannot be acquired overnight.

Under a unified manufacturing framework that spans design to production and materials, we utilize multiple technologies to meet the diverse needs of our customers.

- Manufacturing Technology

We select the optimal manufacturing process, such as injection molding or vacuum forming, based on the product specifications.

- Design and Engineering Technology

We perform mold design and coating design according to the custmer requirements.

- Material Technology

We blend materials for production to ensure the required strength and quality of the product.

Technical Information

In our company, we have a wide range of molding techniques and equipment to meet various needs.

We have established an environment with meticulous quality and hygiene management.

Injection Moldings

Injection molding is a forming technique suited to large-scale production of products with complex shapes. We use injection molding mainly for things like logistics industry materials, industrial components, medical related products, household products, commercial-use goods, and construction and engineering materials.

Production system of Food Packaging Containers

We consider food packaging containers as an integral part of the food itself. With a focus on achieving stable supply and the principles of safety and reliability, we have established an integrated system for producing finished products from sheet materials. This comprehensive approach ensures excellent overall quality in terms of hygiene, product quality, delivery time and cost performance.

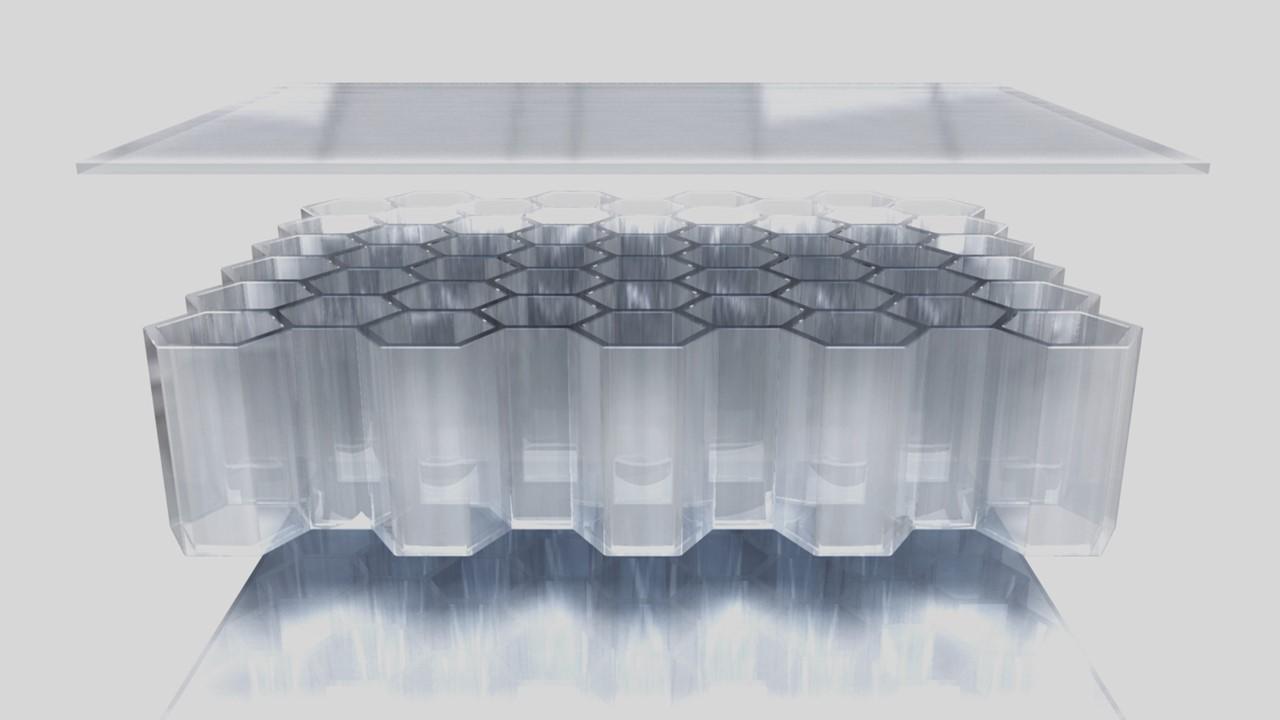

Honeycomb Core Material Continuous Molding Technology

The forming technology of Honeycomb core material TECCELL

The honeycomb core is a dynamically outstanding sandwich-type core comprising a cluster of hexagonal cells. Strength per unit weight it is said to be the best among all types of structures.

Strive for a Sustainable Society

As a technology-driven company, we develop environmentally conscious products to achieve a sustainable society. We are not limited to existing technologies, and we are challenging ourselves to develop new technologies to build a circular economy.