Production of Food Packaging Containers

Technologies of RISU Plastic Group

Molding

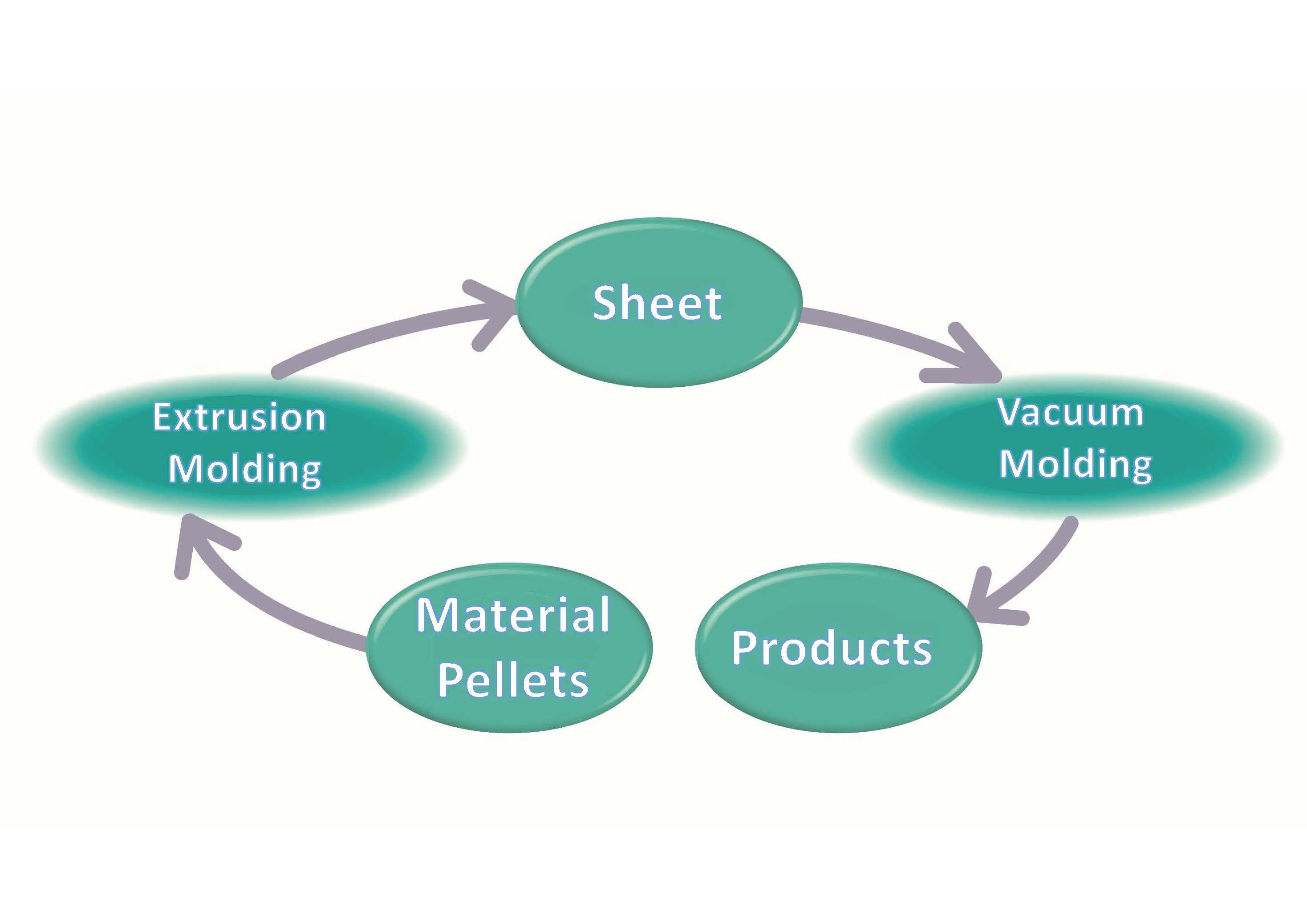

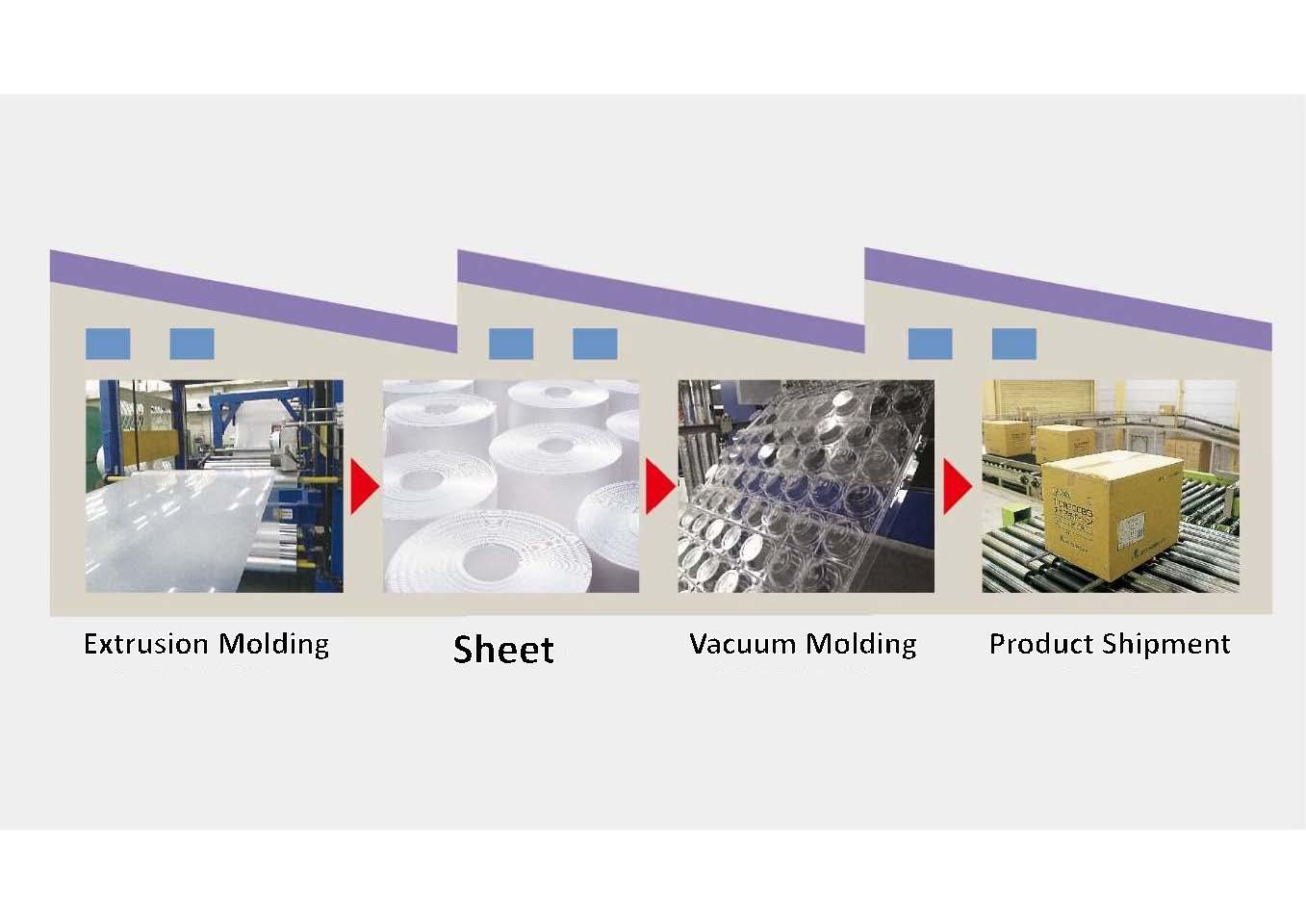

The production of food packaging containers involves the extrusion molding of sheets, which are subsequently vacuum-formed into the desired product shapes. Risupack maintain end-to-end system from sheet material to finished products, ensuring exceptional comprehensive quality encompassing hygiene, delivery schedules, cost-efficiency, and performance.

Extrusion Molding

Molding Cycle

Vacuum Molding

Production System for Ensuring Safety & Quality Assurance

Considering food packaging containers as an integral component of the food itself, we have established a production system aimed at achieving stable supply and the realization of safety and peace of mind.

HACCP compliant Hygiene Management

- We have established clear hygiene management zones, and we strictly enforce proper hygiene procedures during entry and exit of rooms

- We use medium efficiency filters to ensure cleanliness at food factory levels

Product Safety Management

From sheet forming to final production, we operate a safety system for completing manufacturing within the same factory, so that the material never leaves the building.

Measures to Prevent Foreign Object Contamination

- Within the clean area, crane-less and duct-less system is adopted to prevent dust particles from setting.

- We segregate areas where plastic and paper dust is generated, as well as the cardboard assembly area.

- In our exhaust system, insect-proof filters are instaled to enhance sanitary conditions.