Establishment in 1953

"Encountering New Materials"

In April 1953, just a few years after the end of World War II, Gifu Plastic Industry was founded in Gifu City, a region still marked by the aftermath of wartime air raids.

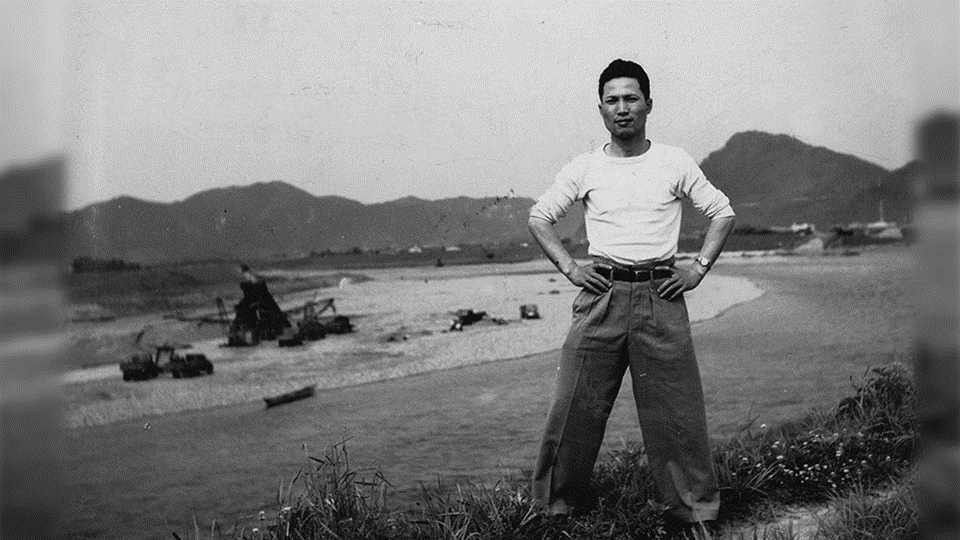

The company was established by a young entrepreneur, Koei Omatsu, who was just 28 years old at the time.

Establishment in 1953

Founder, Koei Omatsu

The founder of Gifu Plastic Industry, Mr. Koei Omatsu, saw great potential in a relatively unknown material—plastic—during Japan’s challenging post-war era.

Observing the early signs of a material revolution unfolding overseas, he became convinced that plastics would play a key role in shaping the future. With strong determination, he made the bold decision to leave his job at a textile company and take on the challenge of starting a plastics manufacturing business.

This pioneering decision marked the beginning of the “CHALLENGE” spirit that still drives the Risu Plastics Group today.

Establishment in 1953

Installation of the First Injection Molding Machine

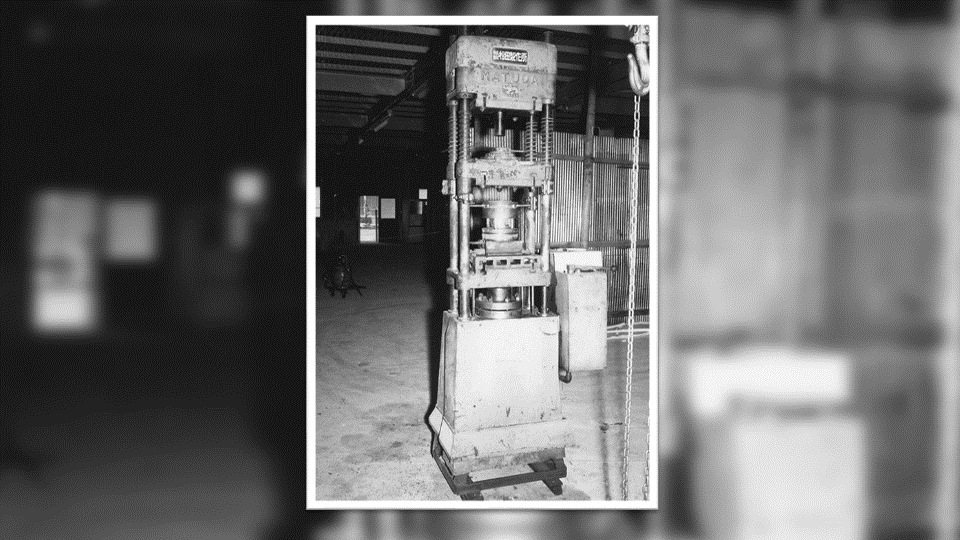

Our First Step into Plastics: A Symbol of Challenge

At the time of our founding, we launched the business from the ground up—with virtually no capital, no credit, and no industry connections.

The first plastic molding machine we acquired was a Japanese-made prototype, purchased for approximately 1 million yen—equivalent to around 6 million yen today (approx. US$38,700 as of June 2024). While more advanced machines modeled after foreign equipment were available, our limited financial resources made this humble yet practical choice the best path forward.

Installed in June 1953, this first vertical injection molding machine stands as a powerful symbol of the Risu Group’s pioneering spirit. Today, it remains proudly on display at our main factory office in Kakamigahara City, Gifu.

Establishment in 1953

Milestone Moment: First Shipment of the Compact Case

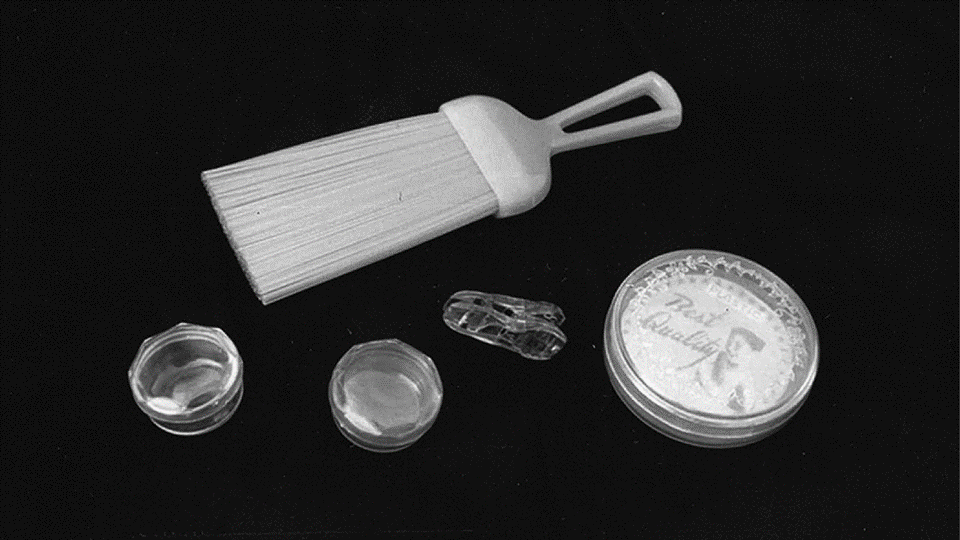

Soon after the company was founded, we began producing items such as frozen containers for ice cream and bobbins for thread spools. However, these early attempts brought little commercial success.

Then, in September 1953, while cycling around Osaka City in search of business opportunities, our founder received a pivotal order from Kansai Plastic Trading Company—for a round compact case to hold cosmetics.

Working tirelessly through the nights, he refined the mold design and made numerous trips between Gifu and Osaka to deliver prototypes. Finally, in late November of that year, the first batch of 500 units was successfully completed.

At the time, plastic was still a rare and novel material. Rather than being sold in the cosmetics section, the compact cases were displayed in the jewelry department—underscoring their uniqueness and perceived luxury.

Establishment in 1953

The Story Behind Our Logo: Inspired by the Squirrel

In 1957, we established our first trademark to help identify our products and strengthen their brand image. Several animals were considered, but the squirrel was chosen for its lovable nature and industrious habit of storing food in the summer to prepare for the winter. It reflected our hope that our products would be just as cherished and dependable.

Our original logo featured an illustration of a squirrel. As our sales representatives visited customers, our products gradually came to be known as "Risu's Plastic," helping solidify our brand recognition.

In 1989, on the occasion of our 35th anniversary, we introduced a redesigned brand logo. The new design adopted red as the primary color, with a bold upward stroke forming the letter “R” to symbolize freedom and creativity. The white “R” within represents the expanding unity of our group. This new logo powerfully expresses RISU’s continuous leap toward the future.

Iconic Products of the Era

Year of 1953-1990

Riding the wave of Japan’s rapid post-war economic growth, the plastics industry entered a golden era. During this time, Gifu Plastic Industry introduced a series of hit products and expanded into new business areas—including food packaging containers, PVC pipe fittings, and logistics containers. These innovations not only supported daily life, but also came to define the era.

Iconic Products of the Era

A long lasting classic : The Plasket

In the fishing and agriculture industries, one enduring product that has become a true staple is the “Plasket,” first introduced in 1964. The original model, No. 800, remains in production today with the same specifications—a testament to its lasting design and practical value. The name “Plasket,” a combination of “plastic” and “basket,” continues to be widely used as a familiar nickname.

To promote its release, a dramatic demonstration was staged in which the Plasket was pulled by a 4-ton truck to prove its outstanding durability. This striking display captured public attention and firmly established the product’s reputation for strength and reliability.

Iconic Products of the Era

Plastic Tub

In traditional plastering, tubs — known as PLA-FUNE — have long been used for mixing mortar, cement, and other wall materials. These tubs were typically made of iron or wood. In 1966, we introduced a plastic alternative called the PLA-FUNE. Unlike iron tubs, which were prone to rust, the PLA-FUNE was lightweight, durable, and quickly gained popularity among professionals.

During Japan’s period of rapid economic growth, the surge in housing construction drove a sharp increase in demand for plastering tools, accelerating the widespread adoption of plastic tubs.

The PLA-FUNE’s distinctive green color was intentionally selected to match the hue of traditional iron tubs, easing the transition for plasterers accustomed to older materials. Over time, this green became a defining characteristic of our tubs—an iconic and trusted presence on construction sites across Japan.

Iconic Products of the Era

"Très Bien" – A Timeless Icon of Japanese Dining Culture

First released in 1972, the Très Bien condiment set quickly became a symbol of premium tabletop design. Its rounded silhouette, crafted from clear acrylic resin, conveyed a refined transparency and sense of luxury. The set’s substantial and elegant design helped establish it as the best-selling series of its kind—both in longevity and in volume.

During the golden era of television, Très Bien was a staple on the dining tables of popular drama series, reinforcing its reputation as a product that defined the lifestyle of its time.

Building on this legacy, its successor, BLOOM, introduced a cherry blossom motif that brought a fresh yet familiar elegance to modern tables. In recognition of its distinctive form, BLOOM was officially registered as a three-dimensional trademark in 2020.

Iconic Products of the Era

High Cooker – A Pioneer in Heat-Resistant Packaging

Launched in 1987, the High Cooker was a groundbreaking heat-resistant container capable of withstanding temperatures up to 275°F. It gained widespread popularity as a packaging solution for take-out meals from convenience stores.

During the 1980s, Japan saw the rapid growth of convenience stores as a new retail format, along with the widespread adoption of microwave ovens in households. This shift created a strong demand for microwave-safe food containers—High Cooker was developed in response to this need.

The product quickly secured a leading position in the convenience store sector. Its success was further amplified by continued product innovations, such as a specially designed base shape that improved product visibility when displayed in supermarket settings. These thoughtful design enhancements earned it a strong reputation and recognition under the name Heat-Resistant RISUPACK.

Iconic Products of the Era

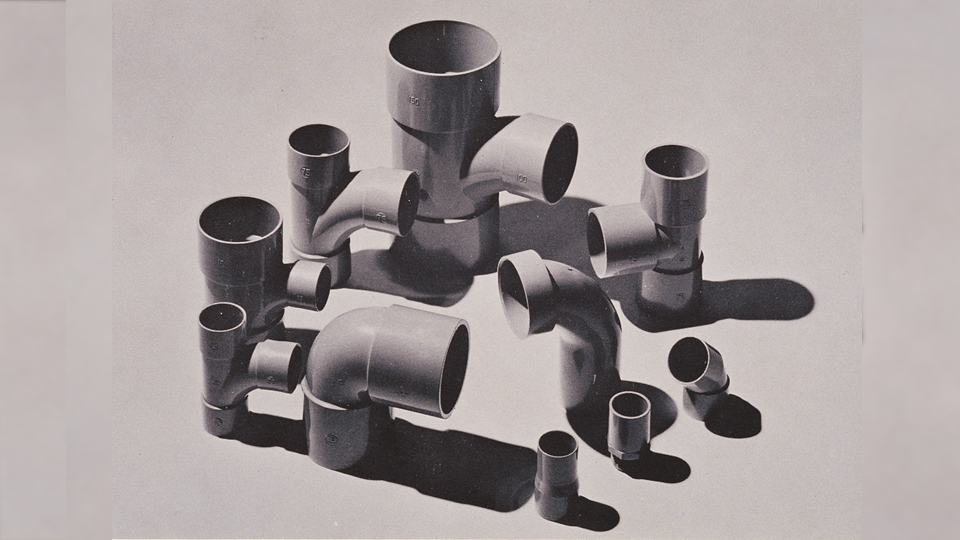

Pioneering PVC Pipe Fittings – Building the Foundations of Infrastructure

In the 1960s, as competition grew in the household goods sector, Gifu Plastic Industry identified rigid PVC pipes as a promising new business. Since producing pipes required large-scale equipment, the company focused on manufacturing PVC pipe fittings—essential components that connect plumbing systems.

Recognizing the inefficiency of each pipe manufacturer producing over a hundred fitting types, Gifu Plastic Industry proposed a centralized production model. In 1963, after securing contracts with major pipe manufacturers, it launched full-scale production and sales.

This strategic shift led to a diverse range of fittings used in water supply, drainage, and sewage systems, becoming a cornerstone of the company’s contribution to public infrastructure and long-term growth.

Year of 1971-1988

Divisionalization - Driving Growth Through Specialized Expertise

As our product portfolio has grown across a wide range of fields, we have adopted a divisionalized structure to better address the specific needs of each industry. By leveraging specialized operations and focused sales strategies for each sector, we have steadily expanded our business and strengthened our presence in diverse markets.

Year of 1971-1988

Establishment of RISU KOGYO Co., Ltd.

In April 1971, Risu Kogyo Co., Ltd. was established as the first subsidiary of Gifu Plastic Industry. It began as a sales division dedicated to the civil engineering and construction sectors, handling PVC pipe fittings, building materials, and various civil engineering supplies.

Following its establishment, the development of PVC pipe fittings expanded to include water supply and drainage fittings, thin-walled drainage pipes, sewage pipes, and a wide range of related products such as basins for sewage systems. These developments enabled more customer-focused sales activities and product development tailored to market needs.

Year of 1971-1988

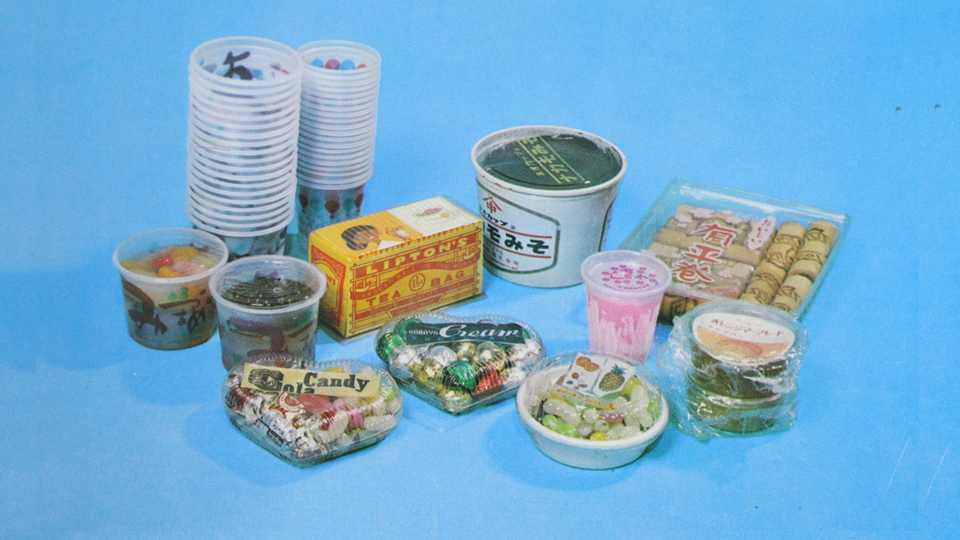

Establishment of RISUPACK Co., Ltd.

In 1975, Risupack Co., Ltd. was established as the second subsidiary of Gifu Plastic Industry to strengthen specialization in food packaging containers. To respond effectively to market trends—often driven by price competition and seasonal demand fluctuations—an integrated organization combining both production and sales was formed.

A key milestone was the introduction of a high-performance, large-scale sheet extrusion molding machine, which enabled in-house sheet production. This not only ensured stable quality but also contributed to cost reduction. The installation of this first machine laid the groundwork for a fully integrated production system, from sheet extrusion to final molding.

Year of 1971-1988

Establishment of RISU Co., Ltd.

Established in 1985, Risu Co., Ltd. became a dedicated entity for the sales and planning of household goods. In response to the evolving and diverse needs of consumers, the company developed a system to create original, high-value products with both long-term vision and short-term responsiveness.

One notable achievement was the joint development of products with MUJI, where Risu played a vital role by providing integrated support from design through to production. This collaboration significantly contributed to MUJI’s product growth and brand development.

To further enhance these planning and development capabilities, Risu Joint Products Co., Ltd. was established in 2005 as a specialized company originating from the joint development division.

Year of 1989-2002

Adapting to Environmental changes

We have responded promptly and effectively to major environmental shifts, including the economic bubble, its subsequent collapse, rapid advances in IT, and the acceleration of globalization.

In parallel, we have proactively pursued product development that incorporates recycled materials and universal design principles. These initiatives have led to significant achievements across a wide range of industries.

Year of 1989-2002

Industrial Containers – Evolving with Industry Needs

The use of industrial containers began in primary industries such as fisheries and agriculture, and later expanded into secondary sectors including automotive and machinery manufacturing. Over time, we developed a diverse range of specialized containers—such as large containers for automotive parts, stackable and conductive containers, reusable two-tone containers, and foldable containers designed as alternatives to corrugated cardboard.

These products, many of which remain in use across various industries today, were engineered to maximize transport efficiency. Among them, our foldable containers were especially groundbreaking. Easily assembled by anyone, they could be reduced to one-fourth of their original size when folded. By meeting the growing demand for efficient distribution, they played a key role in streamlining logistics and optimizing workplace operations.

Year of 1989-2002

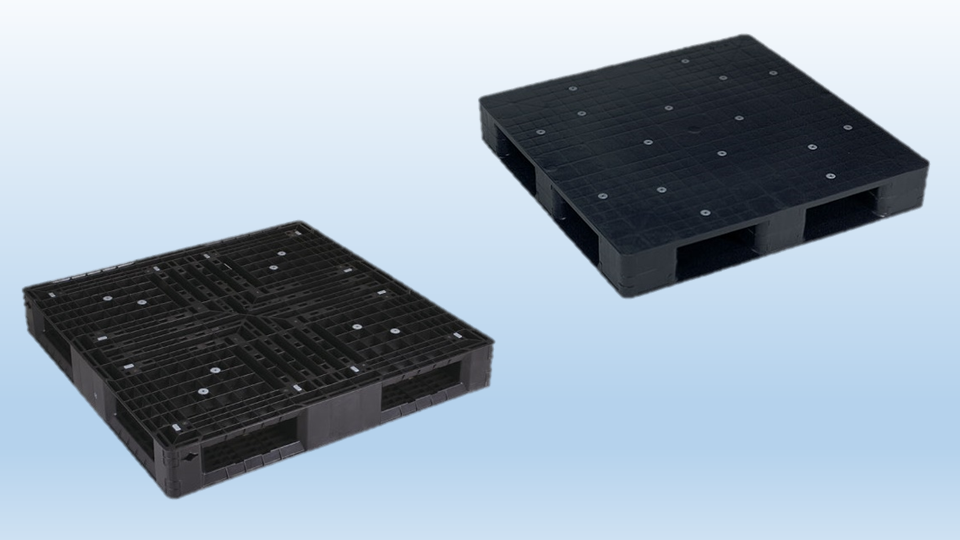

Pallet Market & Recycling Technology

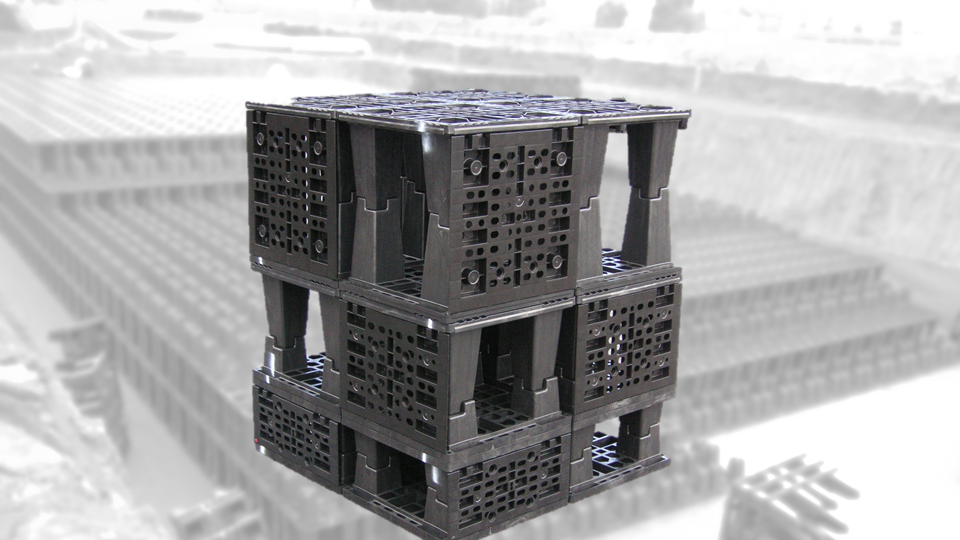

In industries where wooden pallets were once the standard, plastic pallets have gained popularity due to their superior durability, hygiene, and mechanical properties. In 1990, Gifu Plastic Industry introduced large-scale injection molding machines and began full-scale pallet production.

In 1993, the company successfully developed pallets made entirely from recycled materials, laying the groundwork for the widespread adoption of recycled plastic pallets and helping to popularize black-colored pallets across the industry.

Year of 1989-2002

Medical Waste Containers – Supporting Safe and Responsible Disposal

In response to regulations requiring infectious medical waste—such as gauze, bandages, needles, and surgical gowns—to be collected and incinerated in sealed containers, Gifu Plastic Industry developed highly sealed medical pails, launched in 1990.

The illegal dumping of medical waste had become a significant social issue, leading national and local governments to introduce stricter regulations and tougher penalties. As a result, demand for secure, compliant medical pails increased rapidly.

Today, Gifu Plastic Industry continues to innovate by developing containers with enhanced heat resistance, achieved by blending polycarbonate with conventional polypropylene. These containers are designed for repeated use after sterilization, contributing to a safer and more sustainable system for the disposal of infectious medical waste.

Year of 1989-2002

Environmental Innovation – Transitioning to Safer Materials

In 1985, a research paper revealed that Freon gases—commonly used as refrigerants in refrigerators and coolers—posed a serious threat to the ozone layer. In response, Gifu Plastic Industry made a decisive move in 1989 by replacing Freon with butane gas as the foaming agent in its sheet molding processes.

Around the same time, polyvinyl chloride (PVC) was the industry standard for transparent cup containers. However, due to growing concerns about the environmental impact of PVC, Gifu Plastic Industry proactively transitioned to A-PET (Amorphous Polyethylene Terephthalate), a safer and more environmentally friendly material. A-PET has a lower calorific value during incineration and produces CO₂ emissions comparable to paper, making it an exceptionally eco-conscious choice.

Although the switch to A-PET presented technical challenges, we overcame them through continuous improvements in molding technology, equipment, and materials. This led to the successful launch of A-PET containers in the market. Today, our transparent containers—sold under the RISUPACK brand—are recognized as industry leaders in environmental performance.

Our early adoption of butane gas and A-PET resin reflects our enduring commitment to sustainability. We remain dedicated to exploring innovative materials and technologies that reduce environmental impact while delivering safe, eco-friendly packaging solutions to our customers.

Year of 1989-2002

Household Waste Containers – Supporting Smarter Waste Sorting

In the 1990s, as waste management became an increasingly pressing social issue and public awareness of recycling grew, local governments began implementing waste segregation programs. In response, RISU Corporation introduced a horizontally divided waste container in 1993, designed to make household waste sorting more convenient. This innovation marked the start of our Pedal Pale series—kitchen-friendly sorting pails tailored to daily life.

Since then, we have continually expanded our product lineup to meet diverse spatial and practical needs, including three-compartment containers and compact models with both horizontal and vertical configurations. These products have become popular items in home improvement stores across Japan.

At RISU, we remain committed to offering waste containers that adapt to evolving lifestyles and promote more sustainable living.

Year of 1989-2002

Universal Design - Everyday Comfort for Everyone

At RISU Corporation, we have been actively developing everyday products guided by the principles of Universal Design—creating items that are easy to use for people of all ages and abilities.

In 1999, we introduced a line of bathing products called Lasrevinu, a name formed by spelling “Universal” backward. We rethought traditional product sizes and capacities to reduce strain on the lower back when seated, improve comfort during body washing, and enhance the ease of scooping hot water with a bath bucket.

Since the 2000s, Universal Design has become a core philosophy in our product development, leading to the creation of numerous user-friendly products that support a wide range of lifestyles and physical needs.

Year of 1989-2002

PLAWOOD – Advancing Sustainability with Recycled Plastic Wood

In 1992, Risu Kogyo Corporation developed PLAWOOD, a plastic simulated wood product designed to promote environmental responsibility and support the recycling of plastic waste. Made entirely from recycled materials, PLAWOOD provided a stable, cost-effective alternative to natural wood and quickly gained recognition as an eco-friendly solution in the market.

Building on its proprietary molding technology, Risu Kogyo expanded the PLAWOOD lineup to include related items such as simplified steps and planters. As a pioneer in plastic simulated wood, the company’s products have been widely adopted in public infrastructure projects—including parks, walking paths, disaster evacuation routes, and retaining walls—particularly in government and municipal construction.

Today, the PLAWOOD series and other environmentally conscious products continue to contribute to sustainable development and the creation of greener communities.

Year of 2003-2012

Contemplating the Future – Embracing Change for a Sustainable Tomorrow

Recognizing the growing global focus on environmental issues, we proactively began developing eco-friendly products and expanding into new business fields to meet evolving social and environmental demands.

Other Topics

■ Contribution to the Revitalization of the Gifu Station Area ■

In 2005, the headquarters of the Gifu Plastic Group—known as the Dai Gifu Building—was completed in front of JR Gifu Station, the main gateway to Gifu City. This was the first urban redevelopment project in the area, playing a key role in revitalizing the surrounding community.

The building features a rooftop garden and greenery planted along its west-facing wall, creating a calming landscape while helping to reduce wall surface temperatures and mitigate the urban heat island effect.

In recognition of these environmentally conscious efforts, the company received the Minister of the Environment’s Award in a competition organized by the Urban Greenery Technology Development Organization.

Year of 2003-2012

Entering the Medical Field – Advancing into Hemodialysis Components

To establish a full-scale presence in the medical field, we began supplying air filters for hemodialysis blood circuits in 2005.

In 2009, we further expanded our involvement by successfully receiving orders for caps used in dialysis equipment from a major medical device manufacturer.

Year of 2003-2012

Strengthening Our Fittings Business – Acquisition of Toei Kanki Co., Ltd.

In 2011, we acquired shares of Toei Kanki Co., Ltd. and established it as a subsidiary. Located in Seki City, Gifu Prefecture, Toei Kanki is a specialized manufacturer of PVC pipe fittings and had long been a valued customer of our subsidiary, Risu Kogyo’s fittings sales division.

While Risu Kogyo primarily focused on contract manufacturing for pipe manufacturers, Toei Kanki developed and marketed its own branded products, which were distributed through 12 branches and sales offices nationwide. The company was well known for its commitment to prompt delivery and attentive customer service. With its close proximity to our production facilities, minimal competition in the market, and solid management practices, the acquisition progressed smoothly.

Following the acquisition, Risu Kogyo’s fittings sales division was transferred to Toei Kanki. This strategic integration created strong synergies, significantly increased sales volume, and revitalized our overall fittings business.

Year of 2003-2012

Pioneering Bioplastics – Leading the Way in Plant-Based Packaging

Bioplastics derived from plants are environmentally friendly materials that utilize renewable resources, help conserve petroleum, and do not contribute to increased atmospheric CO₂ levels.

In the 1990s, plant-based resins began gaining attention as sustainable alternatives. In March 2003, Risupack became the first company in Japan to conduct test sales of food packaging containers made from polylactic acid (PLA), a resin derived from plants.

In 2005, Risupack’s PLA container became the first vacuum-formed PLA product certified by the Association of Polyolefin Hygienic Products. These containers were also selected as the official food containers for Expo 2005 Aichi, Japan—further cementing Risupack’s leadership in bioplastic food packaging.

This milestone opened the door for the expansion of bioplastic products into other fields within the group, underscoring our continued commitment to environmental innovation and sustainable manufacturing.

Year of 2003-2012

Declaration of Safety, Security, and Sustainability in Food Packaging

As consumer expectations for food safety and quality continue to rise, Risupack embraces the belief that "containers are also part of the food." Guided by this philosophy, we have issued our Declaration of Safety, Security, and Sustainability, built on the following three core principles:

1. Use of Materials Proven to Be Safe and Secure

2. Implementation of Reliable and Safe Production Systems

3. Development of Bio-based Products and the Realization of a Sustainable Society through Innovative Business Models

This declaration drives our commitment to advancing bio-based packaging and serves as a foundational principle in our mission to deliver safe, secure, and sustainable food solutions for future generations.

Year of 2003-2012

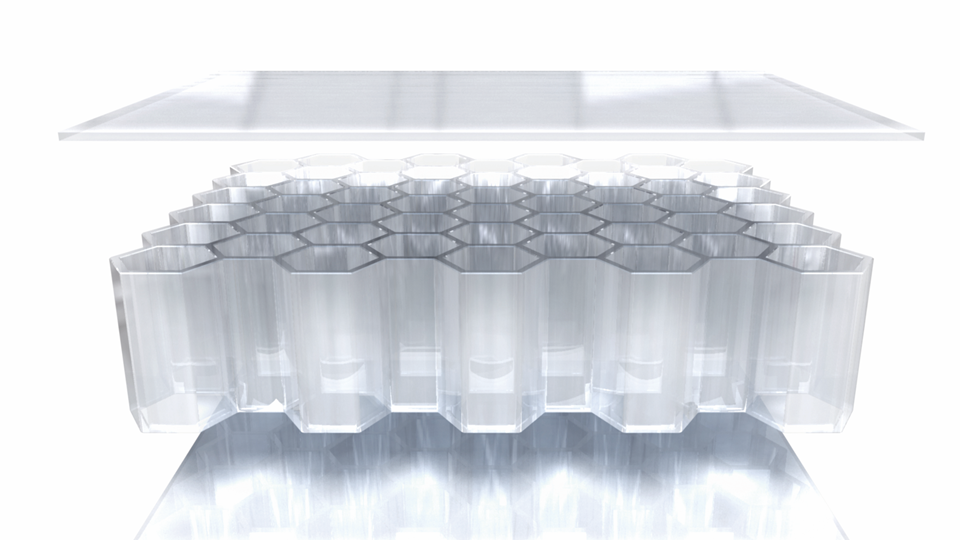

Lightweight Innovation – Thermoplastic Honeycomb Structure

Driven by our commitment to environmentally conscious manufacturing, we set out in search of the world’s lightest resin or structure. With the cooperation of ITOCHU Corporation, we discovered a thermoplastic resin honeycomb structure developed using continuous molding technology at the Catholic University of Leuven in Belgium.

A honeycomb structure consists of a network of beehive-shaped hexagonal cells forming a hollow core, sandwiched between two surface layers. Renowned for having the highest strength-to-weight ratio of any structural form, it is an environmentally friendly material that greatly contributes to weight reduction.

In 2006, we signed a licensing agreement with EconCore, a spin-off from the university, and began commercializing the technology. By developing proprietary production equipment and accumulating in-house expertise, we became the world’s first company to achieve mass production of this advanced material.

Due to its outstanding performance and high level of refinement, the thermoplastic honeycomb structure has attracted significant attention across a wide range of industries and has led to numerous collaborative development projects aimed at addressing real-world challenges.

Year of 2003-2012

Risu Rain Stadium – Contributing to Flood Prevention with Sustainable Innovation

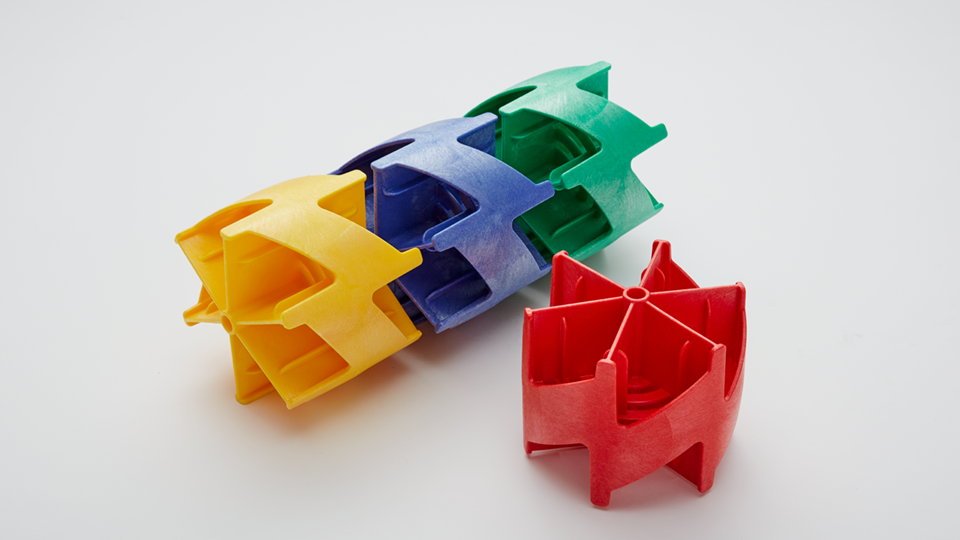

In 2007, in response to the growing risks of localized heavy rainfall and water-related disasters caused by urbanization, we developed the Risu Rain Stadium—a rainwater storage and infiltration tank designed to help control stormwater runoff into rivers.

While concrete tanks were once the industry standard, demand began to grow for lightweight, easy-to-install plastic alternatives. Leveraging our expertise as a leading injection molding manufacturer, we successfully developed a high-performance tank that improves on-site efficiency, reduces costs, and ensures consistent quality.

The tank’s use of recycled materials has also been recognized for reducing environmental impact. Since its introduction, the Risu Rain Stadium has seen widespread adoption in both public and private construction projects, solidifying our position in the rainwater management sector.

As climate change continues to drive more frequent and intense rainfall events, demand for our solution is expected to grow. We remain committed to meeting this demand and contributing to the creation of safer, more resilient communities.

Year of 2013 - Present

Creating Products That Meet Societal Needs

We have developed a wide range of products across our business fields with the goal of balancing everyday convenience with environmental responsibility—striving to be a company that continuously contributes to society.

Other Topics

In 2015, TECCELL’s groundbreaking mass production technology and product development—recognized as the world’s first successful large-scale production of its kind—was honored with the Minister of Economy, Trade and Industry Award in the Product and Technology Development category at the 6th Monodzukuri Nippon Grand Awards.

TECCELL received high acclaim for its innovative potential and versatility across a wide range of applications.

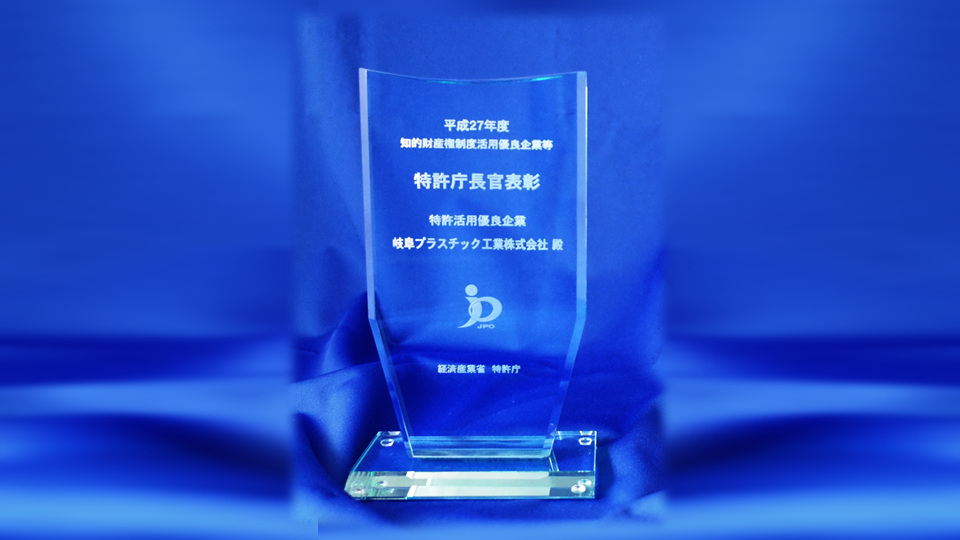

In 2015, we were honored with the Patent Commissioner’s Commendation at the Intellectual Property Achievement Awards, hosted by the Ministry of Economy, Trade and Industry, in recognition of our contributions to the advancement of the intellectual property rights system.

Our proactive efforts to protect and effectively utilize intellectual property were highly praised.

■ Regional Future-Leading Companies ■

In 2018, Gifu Plastic Industry and RISUPACK were selected by the Ministry of Economy, Trade and Industry as Regional Future-Leading Companies in recognition of their strong potential to drive regional economic growth.

■ Risu Logistics Co., Ltd. ■

In 2019, in response to the growing logistics crisis, we acquired Hashizume Transportation, a transport company operating in the Kanto region, to leverage its extensive delivery expertise and enhance the precision and efficiency of our distribution operations.

In March 2025, the company was renamed Risu Logistics Co., Ltd., marking a new chapter in its evolution. Through this rebranding, we aim to further strengthen our transportation capabilities and contribute more broadly to the growth and success of the Gifu Plastic Group.

■ RISU AMERICA, INC. – Indiana Factory – ■

Gifu Plastic Industry Co., Ltd. has established its first overseas subsidiary, RISU AMERICA, INC., in the United States, and is currently constructing a new manufacturing facility in Indiana. Construction began in April 2024, with operations scheduled to begin in September 2025.

Year of 2013 - Present

Expanding the Use of Bioplastics – Leading the Way in CO₂ Reduction

Gifu Plastic Group continues to lead the industry in efforts to reduce CO₂ emissions through the adoption of biomass plastics. Beginning with food packaging containers, we have steadily expanded our use of bioplastics across diverse sectors—including household goods such as pails, sports equipment like pool materials, and logistics applications such as pallets, containers, and carriers.

With growing global demand for renewable alternatives to petroleum-based resources, we recognize the urgent societal need for the practical application of plant-derived plastics. Since the late 1990s, we have been engaged in continuous research and technological development in this field. In recent years, we have collaborated with government agencies, material suppliers, and equipment manufacturers to commercialize and promote bioplastic products.

Our early success in bringing these products to market—well ahead of others in the industry—is a testament to our long-standing commitment. As we look to the future, we remain dedicated to expanding the use of bioplastics into new areas and driving progress toward a more sustainable society.

Year of 2013 - Present

TECCELL-SAINT – Advanced Soundproofing for a Better Work Environment

We discovered that by adding small perforations to the surface of TECCELL, our proprietary honeycomb core material, it gains excellent sound-absorbing properties. In 2017, we launched TECCELL-SAINT, a soundproof panel developed to address industrial noise challenges.

Since its debut, we have received numerous inquiries from companies aiming to improve acoustic conditions in noisy factories or resolve noise complaints from nearby communities. Over the span of four years, we have successfully addressed more than 600 noise-related issues, contributing to better workplace environments and stronger community relations.

Furthermore, TECCELL’s combination of lightness and strength has led to its adoption in joint development projects for jet engine sound-absorbing panels, in collaboration with the Japan Aerospace Exploration Agency (JAXA) and IHI Corporation.

As awareness of employee health and well-being continues to grow, addressing noise in factory environments—where excessive sound can be a serious burden—is becoming increasingly important, particularly in Japan’s manufacturing sector, which faces ongoing labor shortages. TECCELL-SAINT remains a highly practical, user-friendly solution with steadily growing demand across industries.

Year of 2013 - Present

Competition Lane Marker – Designed for World-Class Performance

In 2017, we developed the RL-150T Competition Lane Marker with the goal of providing athletes with the optimal competitive environment. This product, selected for installation at the Tokyo Aquatics Centre, was specifically engineered to minimize the wave interference that occurs during swimming.

To objectively measure wave reduction performance, we established our own standard in collaboration with experts in oceanography and hydraulics. Guided by this framework, we designed a uniquely shaped lane marker that delivers the highest level of wave-dissipating functionality, verified through extensive research and testing.

Beginning with its use at the 2017 Ehime National Sports Festival, adoption of our lane markers has steadily expanded to certified pools across Japan.

We are especially proud that in 2021, our RL-150T lane markers were chosen as the official equipment for the swimming venue at the Tokyo Paralympics—a testament to our commitment to quality, innovation, and supporting athletes at the highest level of competition.

Year of 2013 - Present

Bringing Containers Closer to Tableware: The “On-the-Table” Concept

Guided by the concept of bringing “containers” as close as possible to “tableware,” we developed White PET PureWhite®—a new material that achieves a smooth, radiant whiteness reminiscent of fine porcelain.

This innovation enables the creation of food containers that not only fulfill their practical role but also enhance the visual appeal of any dining experience. With its elegant finish and refined appearance, PureWhite® supports a wide variety of menu presentations and elevates the quality of food display.

Thanks to its versatility and bright, glossy surface, PureWhite® has gained strong attention in the supermarket industry and has already been adopted by numerous retailers for its exceptional aesthetics and performance.

Year of 2013 - Present

Advancing Sustainability with Biomass Plastic Containers

Since the introduction of our PLA-based material BioNeut, we have developed a wide range of biomass plastic containers to meet diverse needs across the market.

Our lineup includes:

PLA-H: A heat-resistant container made from natural PLA materials

BioDelica: A partially plant-derived plastic container

BioCups: Highly transparent cups widely used for fresh produce and salads

EcoA: A PLA hybrid container offering both heat resistance and clarity

BioHIPS: A glossy material extensively used for sushi and sashimi containers (as of 2020)

By 2023, biomass plastic containers accounted for over 47% of our total container sales—a clear indicator of both market demand and our rapid growth in this field.

As a leading innovator in biomass plastic container solutions, we remain committed to expanding our product offerings and contributing to the creation of a sustainable, recycling-oriented society.

Year of 2013 - Present

Trunk Cargo – A Timeless Standard in Storage

Trunk Cargo is a durable and reliable storage box that has withstood the test of time. For over two decades, it has transcended changing trends and values to become a trusted staple in the market.

Since its launch in 1998, Trunk Cargo has featured a large, easy-to-carry buckle and a robust load capacity of 100 kg (220 lbs). More than 20 years later, it continues to be produced and embraced as a versatile storage solution—perfect for outdoor activities, DIY projects, garage organization, and even indoor use.

Its rugged yet minimal design, combined with practical functionality, has earned lasting popularity and widespread appeal. Trunk Cargo remains a dependable, timeless choice that delivers long-term value—unshaken by passing trends.

Year of 2013 - Present

Innovative Double-Layered Pipe Joints – Enhancing Safety and Efficiency

In 2011, revisions to the Water Pollution Prevention Act mandated the use of materials and structures capable of preventing the leakage and underground seepage of water containing hazardous substances. This regulatory shift created a strong demand for double-layered piping systems.

At the time, the standard method involved cutting and bonding two separate pipe joints—a process that was labor-intensive, time-consuming, and costly. To address these challenges, TOEI KANKI developed an innovative double-layered pipe joint that can be molded seamlessly as a single unit, eliminating the need for additional processing.

This breakthrough solution offers numerous advantages: it reduces overall costs, shortens lead times, improves safety, and simplifies installation—contributing to greater efficiency in construction projects.

A transparent version of the joint is also available, allowing for quick visual inspection and early detection of leaks. This feature significantly enhances facility maintenance by enabling faster response to issues, and has earned widespread recognition for its practicality and reliability.

- HOME

- Group Information

- History of RISU Plastic Group