Products that Leverage the Secondary Processing Capabilities

Good workability of the material creates product originality (uniqueness).

Case1 Processing the END SIDE of the board

Thermal processing of the end side of the board

Partial processing

The final processing can be customized to suit the application, ensuring that neither functionality nor design is compromised.

Additionally, this process enhances the design while also improving the strength, washability, and safety of the edges.

It is utilized in a diverse range of products, including logistics packaging materials, interior furnishings, displays, signage, and building materials (interior materials).

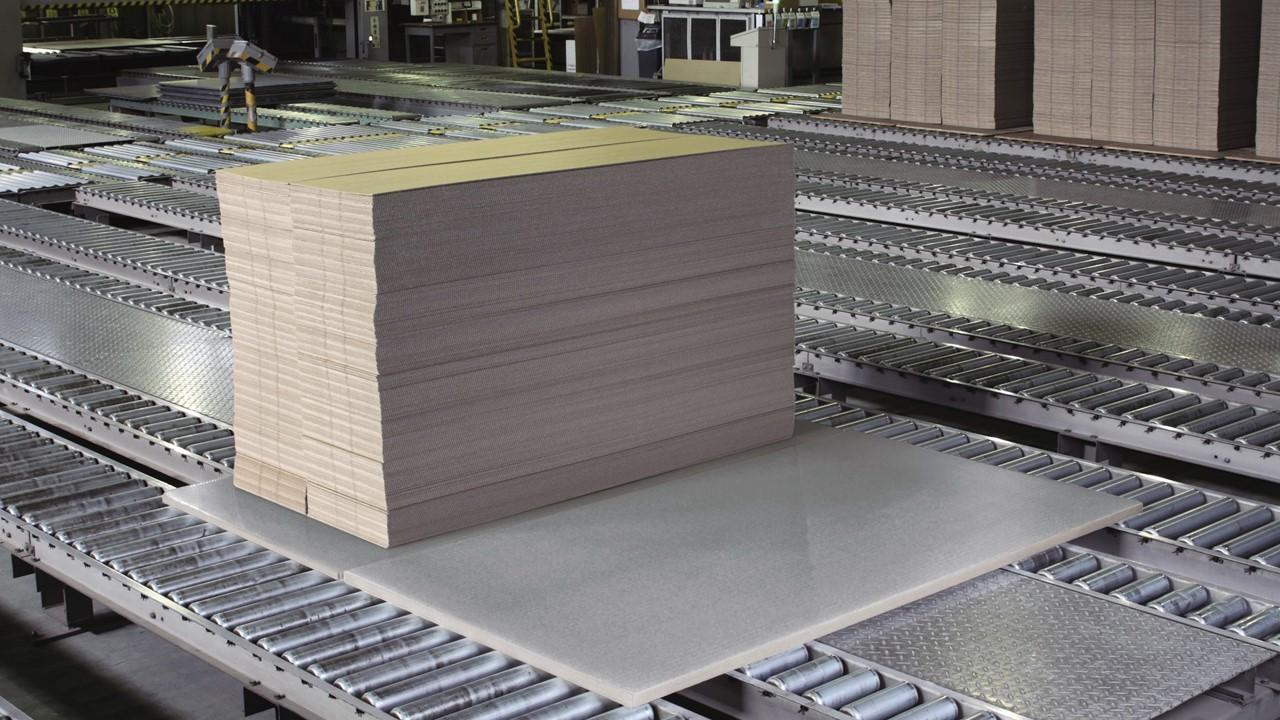

(e.g.)Line Pallets

(e.g.) Display Boards

(e.g.)Lightweight Table Tops

Case2 Bending Processing

Thermal Bending

Thermal Creasing(V-cut)

Thermoplastic resin's properties allow for bending through heating. This feature is utilized in products such as logistics packaging materials and displays.

(e.g.)U-shaped Pallet Box

(e.g.)Box without lid

(e.g.)Multipurpose Display Stand

Case3 3D Processing

Vacuum Forming #1

Vacuum Forming #2

Cells remain perpendicular to the surface

TECCELL's 3D processing maintains rigidity by keeping the cells perpendicular to the surface. This allows TECCELL to maintain high strength for any shape, including free-flowing curves.

It is used in a wide range of products, including automobiles, sports equipment, interior components, and signage.

(e.g.)Swim Training Paddles

(e.g.)Chair Core Material

(e.g.)Protective Gear for Motorcycle Riders

Case4 Welding Processing

Resin Welding

Fusion Welding

Processing Examples(Joining Process)

We can accommodate various applications and can be produced in any size. This characteristic is utilized in products such as logistics packaging materials, displays, signs, and building materials (interior materials).

(e.g.)Connection to Pallet Legs